Commercial Brewing Equipment and Understanding Hot Side

Hot Side vs. Cold Side

Whether entering the world of professional brewing or looking to brush up on knowledge for homebrew operations — understanding commercial brewing equipment is beneficial for brewers of every type. There are two major categories of equipment and tasks when brewing: hot side and cold side.

Hot side refers to the addition of heat during the early steps in the process, and cold side is the suppression of heat that happens after. The main hot side operations include mashing, lautering, boiling, and whirlpool. The primary cold side operations are fermentation, conditioning, and packaging. These two major categories are separated by a heat exchanger, which removes heat from the wort during transfer into the fermenter.

Each process and operation requires its own set of equipment and understanding. Working from the beginning of the beer-making process will lead to a better understanding of the brewing equipment and provide additional insight as to why each piece and component is important.

Mashing In

Mashing — the term given to the start of the brewing process. It’s where crushed grains are mixed with water to form a mixture called the mash. In the mash, malt and other starches are transformed into sugars and proteins and create the wonderful liquid known as wort. There are three basic pieces of equipment that are needed to perform a commercial mash:

- Grain mill to crush the malt

- Mash tun to allow enzymatic conversions to take place

- Lauter tun to separate the grains from the sugar-filled wort

In some cases, mash tuns and lauter tuns are combined into a single vessel, reducing the cost and floor space needed when using separate mash and lauter tuns. Whether using a combination mash-lauter tun or going with separate vessels, these two pieces of equipment and a mill are necessary for a commercial brewery.

Malt mills live somewhat outside of the hot side of brewing since heat has not yet been added to the process. They are an integral part of mashing that comes in many different types and sizes. Homebrewers may be familiar with a corn cracker or small-scale mill, but commercial breweries require one that can quickly process hundreds of pounds of malt. Hammer mills are useful in certain situations, but the roller mill is the most common. To crush malt, a roller mill uses a combination of mechanized rolling pins sitting below a grain hopper. These mills are connected to augers which can carry the crushed malt to the mash tun immediately or to a super sack where the crushed malt is captured before the mash tun addition.

Glacier Tanks works with RMS Roller Grinder for mills and augers in our brewery buildouts and can help source a proper mill for your application.

Mash Tuns

Much like mills, mash tuns come in many varieties. The purpose of mashing is to convert starches to sugars by allowing enzymatic processes to take place at specific temperatures. This makes insulation the key feature for a mash tun.

Some mash tuns have motorized rakes to stir the mash, and some only have a large access lid requiring brewers to stir the mash with a paddle instead. For those who opt for a steam system, a steam jacket is a feature that is available for mash tuns. This allows for efficient heat control during the mashing process but is only used by breweries that use a steam boiler to power their equipment.

Lauter Tun

Once the malt has been mashed, the wort is separated from the leftover solids, known as spent grain. This process is called lautering and is performed in a vessel called a lauter tun. Lautering has three simple steps: transfer mash into the lauter tun, vorlauf, and sparge.

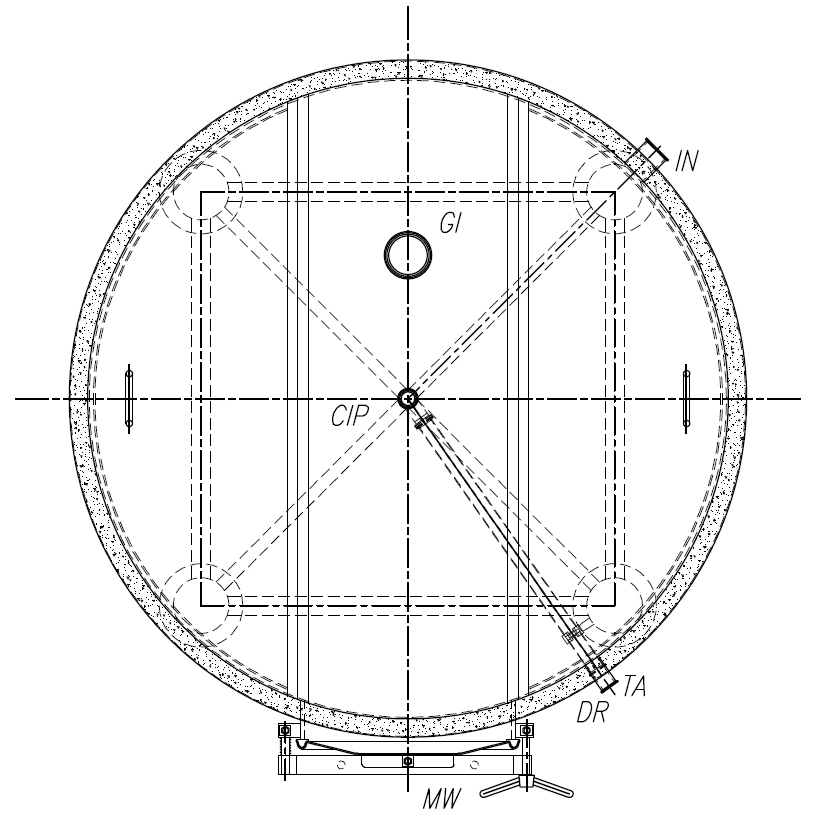

Once the mash has been pumped from the mash tun into the lauter tun, many brewers opt to recirculate the wort through the grain bed to help it settle, which will itself act as an additional layer of filtration for finer particulates. This process is called vorlauf (or recirculation) and requires a lauter tun that has been manufactured with the components and proper porting arrangements to allow for the recirculation loop. A commercial lauter tun must also be manufactured with the proper piping and porting arrangements for sparging, which often includes a specialized sparge arm or sparge ring to distribute water evenly over the grain bed.

An important note when considering lauter tuns is that they are fitted with a false bottom sitting a small distance above the bottom of the mash tun. This false bottom is often a perforated sheet of stainless steel, a stainless steel wedge wire screen, or a stainless steel milled screen.

- Perforated screens are the most affordable but are less effective than wedge wire or milled screens.

- Wedge wire screens have the greatest amount of surface area for filtration and have superior filtration properties compared to perforated screens. However, they cost much more and have many more weld points. This makes them inherently more prone to maintenance concerns over time.

- Milled screens have slightly less surface area for filtration when compared to wedge wire screens, but they have comparable filtration properties and are less prone to maintenance problems. These properties have made milled screens a popular choice for lauter tun filtration in today’s breweries.

Mash-Lauter Tuns

Glacier Tanks can manufacture individual mash and lauter tuns, but most of our designs utilize a combination mash-lauter tun. This is a common combination where the mash tun is fitted with a false bottom and manufactured with all the correct piping, ports, and fittings to allow for vorlauf and sparge to occur all within a single mash vessel. This mash-lauter tun is the preferred choice of many small and medium breweries because space is often one of the most crucial resources for small businesses. On top of that, it saves you one major expense, which is the cost of a pump that is capable of pumping thick mash with heavy particulate content between vessels. This combination is not without its drawbacks, however. If they do not start out this way, many breweries will quickly find that they must make multiple batches per day to keep up with demand. Using two separate vessels for mashing and lautering allows you to begin mashing your next batch as soon as you’ve transferred it into the lauter tun. This can be a major time saver, especially if brewing four batches per day.

Boil Kettles and Whirlpool Vessels

After mashing and filtering spent grain from the wort, it’s time to boil. And there’s no better equipment for the job than a boil kettle, which can be manufactured with a variety of different heart sources. The main sources of heat used in commercial breweries today are steam, electricity, and indirect fire (gas). No matter which type of kettle you choose, insulation is another major factor since heat loss can impact your boil negatively.

- Steam kettles allow for the most control and efficiency when heating. They will require a steam boiler or generator and a dedicated boiler room. This isn’t a common choice for smaller breweries nowadays, but for large-scale production breweries, steam kettles are the most common due to their large-scale efficiency and manufacturability.

- Electric kettles have grown in popularity but have challenges of their own. Most commonly available electric kettles use immersion heaters that are submersed directly into the wort, and the high sugar content mixed with high heat produced by the elements can lead to scorching. For this reason, it is important that immersion heaters that come into contact with wort be of the lowest watt density possible.

- Indirect-fire tanks use natural gas or propane to power a forced air burner. This forced air burner can be imagined as a 300k BTU hair dryer (but something you certainly don’t want to stand in front of). It is mounted to a firebox that is welded underneath the body of the kettle and blows 1000-degree F air through the firebox and out the exhaust stack. These tanks need commercial all-fuel chimney pipes to handle the heat of the exhaust, which can be quite costly. However, this is a very common heat source for startups and established breweries because of the ease of setup and affordable natural gas prices in many areas.

A whirlpool vessel is used as the final step in the hot side of brewing before the wort is sent through the heat exchanger. The boiled wort is pumped from the boil kettle into the whirlpool vessel, where it is recirculated for a while through a tangential port on the side of the tank. This creates a whirlpool that piles any trub or sediment in the center of the tank. Clean wort is then drained via a port at the side of the tank. This port is often guarded by a small piece of metal (hop dam) so that no errant hops that may have been added during whirlpool make it into the drain port. This separation process is critical when using a plate and frame heat exchanger so that large solids do not clog the heat exchanger.

Boil Kettle-Whirlpool Tank

Just like mash and lauter tuns, the boil kettle and whirlpool vessel can be combined into a single boil kettle-whirlpool tank. All Glacier Tanks boil kettles come fitted with tangential ports and hop dams to facilitate the whirlpool process, but we can build the individual tanks too. This combined vessel is a common combination for the same reason that mash tuns and lauter tuns are combined, and the combination also creates the same drawback. You save on space and cost by having a single tank that can do the job of two vessels. However, if you are doing multiple batches per day at your brewery, it may be worth the time savings to be able to start boiling your next batch while knockout occurs in the whirlpool vessel.

Continue brewing and transfer to the cold side with our next blog.